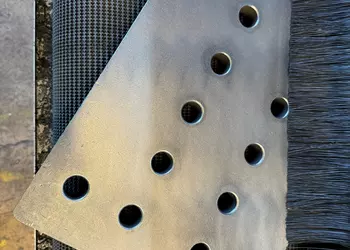

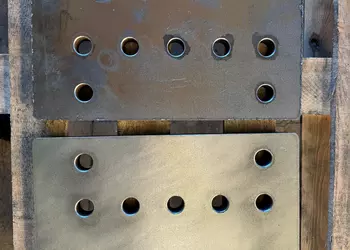

A deburring machine is a precise and versatile tool used for cleaning metal sheets after various cutting processes, characterized by high efficiency and adaptability. The deburring process involves removing scale, sharp edges, oxides, and burrs formed during material processing, such as plasma cutting of carbon steel. Although these imperfections can be microscopic, they may negatively affect subsequent production stages, making their removal crucial. Deburring prepares edges in accordance with standards, enhances workplace safety, improves the aesthetics and functionality of components, and ensures better interaction between parts in machines.

Our deburring machine performs four operations in a single pass:

- Removing scale

- Deburring and edge rounding

- Heavy edge rounding

- Eliminating oxides

The service performed with the deburring machine guarantees consistent quality that cannot be achieved with manual processing. It handles sheets with a thickness ranging from 0.5 mm to 100 mm and a width of up to 1000 mm, allowing work with both small and large parts.