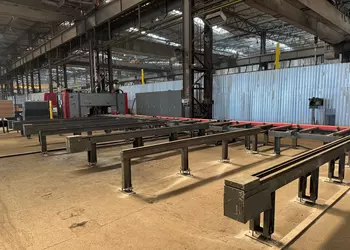

Integrated cutting and drilling with Voortman line

We offer steel cutting and drilling services using an integrated CNC line by Voortman. The process is fully automated – no manual positioning or material handling is required. All operations are performed in a single technological cycle.

With three independent drilling units and Voortman MANUAL BATCHER software, we ensure high dimensional accuracy, repeatability, and significant reduction in lead times. This solution is ideal for prefabrication of steel structures where precision, documentation compliance, and on-time delivery are key.

Technology advantages

- Steel processing: HEA, HEB, IPE, UNP, RHS, SHS, angle bars

- Max profile cross-section: 1050 mm × 445 mm

- Accuracy up to ±2 mm

- Three-sided processing without material repositioning

- Three independent drilling spindles (X, Y, Z axes)

- Drilling speed up to 2000 RPM

- Integration with BIM systems and DSTV/NC files

- Compliance with EN 1090 (EXC1–EXC3)

Precision and repeatability

Every part is manufactured with high precision – regardless of batch size or project complexity.

Operational efficiency

The automated process significantly reduces lead times, minimizes material waste, and optimizes production costs.

Fast

turnaround

Quick quoting, rapid processing, and on-time delivery – without unnecessary delays.

Contact us and receive a free quote tailored to your project

Have a technical question? Want to learn more about the service?

Call: +48 571 217 020

Email: lukasz.dworczak@lebal.com.pl

Contact us